What It Means to Be an ODM Partner with TOMAR

At TOMAR, we are more than a contract manufacturer. As an ODM, we invent, engineer, and build complete product solutions that our partners can brand and sell under their own name. Unlike traditional OEM work where you supply the design, our ODM services include:

- Product design and engineering from concept

- Prototype development and testing

- Manufacturing and supply

- Design ownership options and customization flexibility

This approach helps brands enter new markets faster, reduce design overhead, and leverage TOMAR’s decades of engineering excellence.

How We Deliver Custom Solutions

TOMAR Custom can bring your next product to life in multiple ways — whether you need subtle modifications, complete new designs, or ready-to-market engineered products.

- Adjust existing TOMAR products to meet your functional or aesthetic needs.

- Use TOMAR components as building blocks in your system.

- Leverage TOMAR’s design and engineering capabilities to develop bespoke products from the ground up.

ODM Development Capabilities

We create unique solutions using our expertise in Optical, Mechanical, Thermal, Electrical, and Software development.

Electrical Engineering

Electrical Engineering designs circuits to meet electrical function requirements with a safe design margin. Circuits are designed, simulated, and tested via computer using Altium PCB Design Suite, MATLAB and LTspice. Hardware versions of these designs are verified on the engineering test bench; and using environmental chambers and a screen room for RFI/EMI measurements.

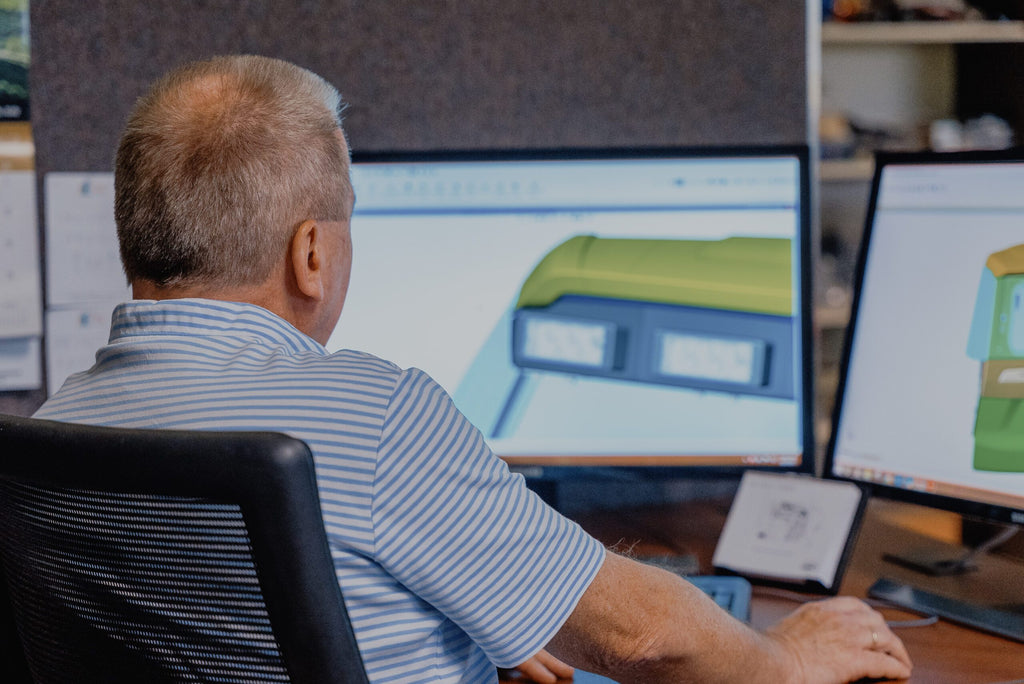

Mechanical Engineering

Mechanical Engineering develops robust product packaging and assembly solutions for physical, structural, and application environment requirements. Computer tools such as Solidworks allow complete design analysis during development through simulation. Employment of a 3D laser scanner facilitates custom fit solutions for a variety of existing hardware applications.

Optical Engineering

Optical Engineering creates and simulates approaches for specific optical outputs, using optical design and ray trace software. Optical designs are incorporated into product part design, and optical output is measured physically to ensure that the physical parts create the desired result.

Software Development

Software Development designs and writes the embedded instructions that drive product functionality. Creative approaches are developed and tested in parallel with hardware design, and are maintained and managed over the life of the product

Thermal Analysis

Thermal Analysis ensures that both circuit designs and physical product designs meet customer product and environmental requirements. Computer simulations and thermal chamber testing allow repeated testing and verification to optimize safe thermal conditions.