Your Products, Your Specs... TOMAR Quality

TOMAR Custom can bring into existence any project as requested to your specifications, in one of three different ways:

- TOMAR Custom Division can modify an existing TOMAR product to meet a specification.

- Existing TOMAR components can be integrated as building blocks into your existing product.

- Leverage TOMAR intellectual property, design capability, and manufacturing expertise to create a completely new solution.

TOMAR Custom Division draws on over 50 years of experience to provide excellence to all existing OEM manufacturers; and at no charge with an executed production commitment. TOMAR Custom Division is your choice for a solution that will outshine and outlast the rest.

CUSTOM PRODUCT DEVELOPMENT

We create unique solutions using our expertise in Optical, Mechanical, Thermal, Electrical, and Software development.

Electrical Engineering

Electrical Engineering designs circuits to meet electrical function requirements with a safe design margin. Circuits are designed, simulated, and tested via computer using Altium PCB Design Suite, MATLAB and LTspice. Hardware versions of these designs are verified on the engineering test bench; and using environmental chambers and a screen room for RFI/EMI measurements.

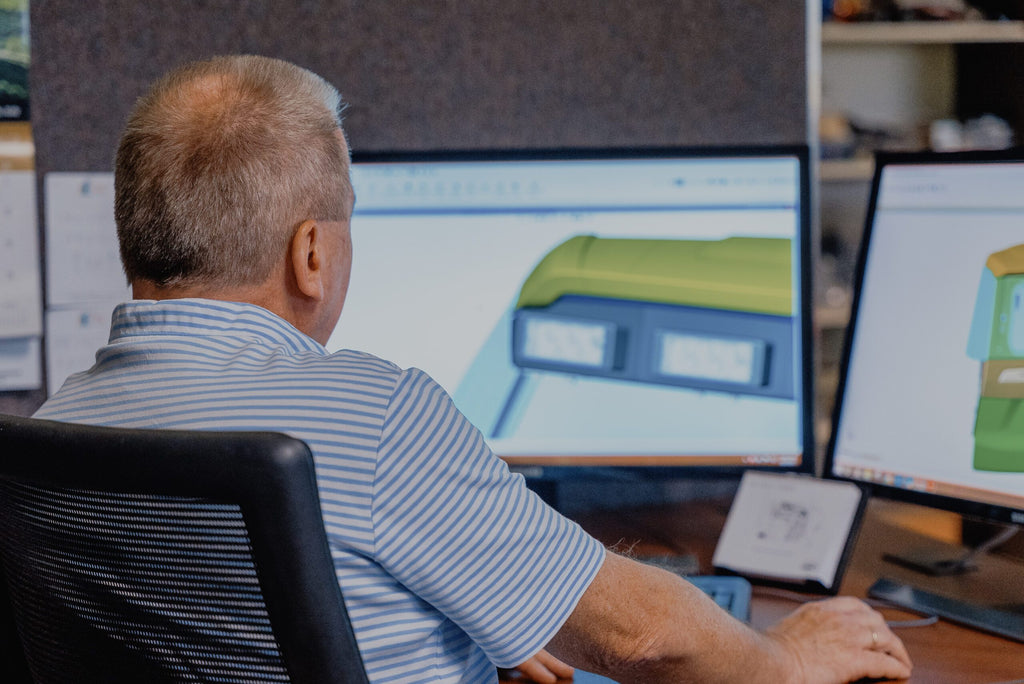

Mechanical Engineering

Mechanical Engineering develops robust product packaging and assembly solutions for physical, structural, and application environment requirements. Computer tools such as Solidworks allow complete design analysis during development through simulation. Employment of a 3D laser scanner facilitates custom fit solutions for a variety of existing hardware applications.

Optical Engineering

Optical Engineering creates and simulates approaches for specific optical outputs, using optical design and ray trace software. Optical designs are incorporated into product part design, and optical output is measured physically to ensure that the physical parts create the desired result.

Software Development

Software Development designs and writes the embedded instructions that drive product functionality. Creative approaches are developed and tested in parallel with hardware design, and are maintained and managed over the life of the product

Thermal Analysis

Thermal Analysis ensures that both circuit designs and physical product designs meet customer product and environmental requirements. Computer simulations and thermal chamber testing allow repeated testing and verification to optimize safe thermal conditions.